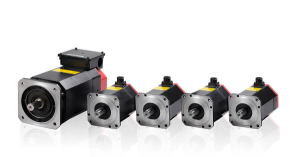

FANUC alpha i Series Servo Motor Repair

FANUC’s Alpha I Series servo motors are compact and efficient servos that provide ultra smooth rotation, quick acceleration, and high speed operation. They are optimized for precision.

These are excellent servos worth keeping around. If yours is in need of maintenance or repair, send it to us and we’ll get it back to you and working like new in no time.

The FANUC AC Servo Motor alpha iS series and alpha i series has been designed for machine tool feed axis applications. This servo motor alpha i series has the following features:

- Smooth rotation - The special magnetic pole shape minimizes torque ripples which, when combined with precise current control and accurate Pulsecoder feedback, enables extremely smooth motor rotation.

- Excellent acceleration - The use of a special rotor shape results in motors that are smaller and lighter than previous models, but which can develop a high level of torque. These motors, therefore, provide excellent acceleration characteristics.

- High reliability - A totally-enclosed, friction-free brushless design is used. This allows the servo motors to be used in demanding environments with no need for special checks or maintenance.

- Built-in, high-precision sensor - A low-indexing-error optical encoder (Pulsecoder) is built into the motors. This Pulsecoder enables precise positioning. Pulsecoders that output 1,000,000 or 16,000,000 pulses per rotation are available. As such, the a series motors can be used for positioning applications ranging from simple positioning to those requiring a high degree of precision.

A & C Electric Company is the leader in FANUC Alpha i Series servo motor repair. We will repair your motor with FANUC OEM parts and guarantee the repaired motor for two years. Our motor repair center in Michigan gives you fast turn-around for servo repairs, especially for customers in the Midwest. Ensuring your FANUC Alpha i Series is back, limiting downtime and helping your bottom line.

If you think your motor’s repair would be too costly or the machine needs to be up and running now, discover our stock of ready to go refurbished FANUC motors.

Servo Lab Capabilities

Servo Lab Repair Procedures

-

Data

Motor nameplate data is recorded

-

Inspection

A visual inspection of any damage to the motor.

We check for- Damaged Leads/Terminals

- Worn output shaft/keyways

- Cracks in end bells or covers

-

Job Ticket

We complete to full write up off all motor data

Including- All winding tests (Resistance, Meg Ω, Continuity)

- All bearing sizes

- All seal sizes

- Brake torque tests (Record Torque, winding resistance)

- Feedback Tests (Tachometer/Encoder)

-

Motor Disassembly

- Bearing and seal sizes are recorded

- Bearing fits are measured on shaft and End bell

- Brake torque is measured as well as resistance and Meg Ω

- More winding tests are performed (Surge and HiPOT tests)

- Stator is then washed and baked in oven

- Magnets are inspected for cracks or if loose on shaft

- Encoder is tested with either (Heidenhain PWM20, Sick PGT-11, or Mitchell Electronics equipment)

-

Assembly

- New bearings are installed

- New seals are installed

- If required, new windings are impregnated

- Brakes are rebuilt or replaced depending on manufacturer design.

- Rebuilt or New encoders are installed and aligned using:

- (Heidenhain PWM20, Sick PGT-11, or Mitchell Electronics equipment)

-

Rotor Balancing and Testing

- Rotor is run through a full vibration diagnostic

-

Run Testing

- Every Motor is Run for a minimum of 1 hour using one of our drives.

- We use Siemens S110, S120, IndraDrive, AB Kinetix 300, Yaskawa 7, and AMC drives

-

Service Report

- A Final 3-page Service Report is filled out

- Pinout diagram for power and feedback is provided

- Brake torque is recorded a final time for our Service Reports

- A photo of nameplate and motor is attached

- A motor tag is installed on motor with QR code linking Service Report and Job Histories

- If requested, a YouTube link is attached to the service report of motor